Profile processing center helps the automotive industry to automate production

August 14, 2024

In the modern automobile manufacturing industry, profile processing centers are becoming an important force in promoting automated production. As the automotive industry continues to increase its requirements for production efficiency and precision, traditional processing methods have become incapable. Profile processing centers, with their high efficiency and precision, are gradually becoming the "new favorite" of the manufacturing industry. This article will explore in depth how profile processing centers can help the automotive industry achieve automated production and what substantial benefits they bring.

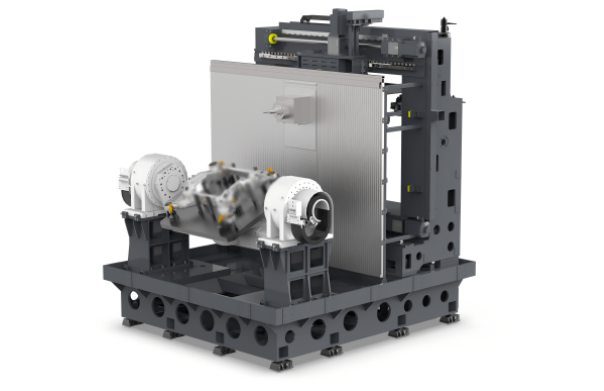

1. The basic concept of profile processing centers

Profile processing centers, as the name suggests, are mechanical equipment used to process various profiles. It usually integrates multiple processing functions such as cutting, drilling, and milling, and can complete complex processing tasks on a single workbench. The core advantage of this equipment lies in its high degree of automation and precision, which can greatly improve production efficiency and product quality.

2. The core requirements of automated production

The complexity of automobile manufacturing determines that every link in its production process needs to be precisely controlled. From the body frame to the internal parts, each component must meet strict technical standards. This requires that the equipment on the production line must not only have efficient processing capabilities, but also be able to operate stably in an automated environment.

Profile processing centers just meet this demand. Its integrated processing function can reduce manual operation, improve processing accuracy, and reduce human errors through automated control systems. These features make profile processing centers an ideal choice for automated production in the automotive industry.

3. Advantages in practical applications

1. Improve production efficiency

In traditional production lines, multiple processing steps often require different equipment and manual operations, which not only increases production costs, but may also cause production delays. The profile processing center integrates multiple processing functions on one device, making the entire production process smoother. For example, a profile processing center can complete multiple tasks such as cutting, drilling, and milling in a short time, significantly improving production efficiency.

2. Improve processing accuracy

The automated control system of the profile processing center can ensure processing accuracy through precise CNC technology. This is especially important for key components in automobile manufacturing, such as engine brackets and body frames. High-precision processing not only improves the quality of components, but also reduces the rework costs caused by processing errors.

3. Reduce production costs The automated processing process can reduce labor costs and production losses. The profile processing center reduces errors and waste caused by human operations while reducing human intervention, thereby effectively reducing production costs. According to statistics, production lines using profile machining centers can save about 20% to 30% in costs.

4. Enhance production flexibility

Modern profile machining centers are usually equipped with intelligent programming and adjustment functions, which can quickly adapt to different production needs. This flexibility allows automakers to quickly adjust production lines to respond to market changes and order requirements. For example, when facing different models of cars, profile machining centers can adjust processing plans by reprogramming, thereby achieving multi-variety small batch production.

IV. Actual Cases

In the automotive manufacturing industry, many leading companies have begun to adopt profile machining centers. For example, a well-known automaker has increased the processing efficiency of the production line by 25% by introducing profile machining centers. In the process of producing body frames, the use of profile machining centers has greatly reduced processing time, while also improving product consistency and quality.

Summary and Outlook

As an important breakthrough in modern manufacturing technology, profile machining centers are bringing revolutionary changes to automated production in the automotive industry. It not only improves production efficiency and machining accuracy, but also effectively reduces production costs and time. With the continuous advancement of technology, profile machining centers will play an increasingly important role in automotive manufacturing.