Aluminum profile CNC processing equipment: creating a perfect combination of precision and efficiency

June 27, 2024

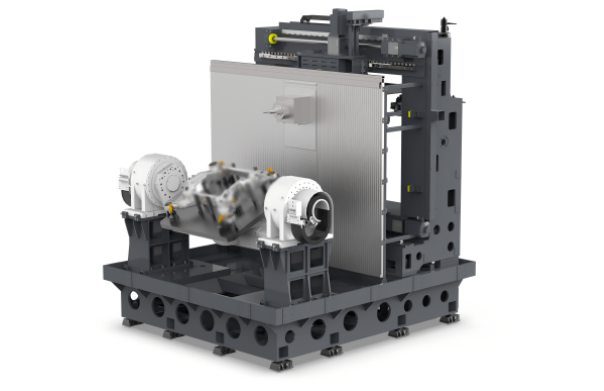

In today's rapidly developing manufacturing industry, precision and efficiency have become the goals pursued by all enterprises, and aluminum profile CNC processing equipment is undoubtedly a powerful tool to achieve this goal. This type of equipment is highly favored for its excellent precision and excellent processing speed, and is the backbone of the production of various aluminum profile products.

Aluminum profile CNC processing equipment occupies an important position in the market with its high precision and high efficiency. These equipment usually use high-quality CNC systems and are capable of complex three-dimensional processing. Whether it is simple plane cutting or complex three-dimensional modeling, it can be completed with extremely high precision. The high degree of automation of CNC equipment greatly reduces human errors, so that the consistency and quality of the product are guaranteed.

This type of equipment is widely used in many fields. For example, in the automotive manufacturing industry, aluminum profiles are widely used to produce lightweight body structural components, and CNC processing equipment can accurately complete the cutting and forming of these components. In industries such as aerospace, electronic equipment, and architectural decoration, aluminum profile CNC processing equipment also plays an indispensable role. It can not only process complex structural parts, but also ensure the strength and stability of the material, thereby improving the overall performance of the product.

Another advantage of aluminum profile CNC processing equipment is its high efficiency. Traditional processing methods often require multiple processes and equipment, while CNC equipment can complete multiple processing tasks at one time, greatly shortening the production cycle. This improvement in efficiency not only reduces production costs, but also improves the market competitiveness of products. For enterprises, investing in such equipment is a wise choice to improve productivity and competitiveness.

The ease of operation and simplicity of maintenance of aluminum profile CNC processing equipment also make it the first choice for enterprises. Modern CNC equipment is equipped with an intelligent operating interface, and users only need simple training to get started. Through preset programs, the equipment can automatically perform precise cutting, drilling, milling and other processing, reducing dependence on highly skilled workers. Even complex processing tasks can be easily achieved through programming, greatly improving production flexibility.

In terms of equipment maintenance, aluminum profile CNC processing equipment has a low maintenance cost. Its core components are usually made of durable materials, with a long life and low failure rate. Many devices also have automatic detection and alarm functions, which can remind operators to perform maintenance in time before a failure occurs, thereby avoiding the risk of production interruption and equipment damage. For enterprises, this not only saves maintenance costs, but also avoids downtime losses caused by equipment failure.

With the continuous advancement of science and technology, aluminum profile CNC processing equipment is also constantly upgrading. Nowadays, many devices have integrated Internet of Things technology, which can realize remote monitoring and data analysis. By real-time monitoring of the operating status and production data of the equipment, enterprise managers can better optimize the production process and improve production efficiency. These data can also provide valuable references for future product development and process improvements, enabling enterprises to maintain a leading position in market competition.

CNC aluminum profile processing center provides a comprehensive solution for modern manufacturing industry with its excellent precision, efficient production capacity and simple operation and maintenance. Whether it is small and medium-sized enterprises or large enterprises, this equipment can meet their production needs and help enterprises achieve lean production and sustainable development. Therefore, choosing a high-quality aluminum profile CNC processing equipment is not only a guarantee of product quality, but also an important investment in the future development of the enterprise.