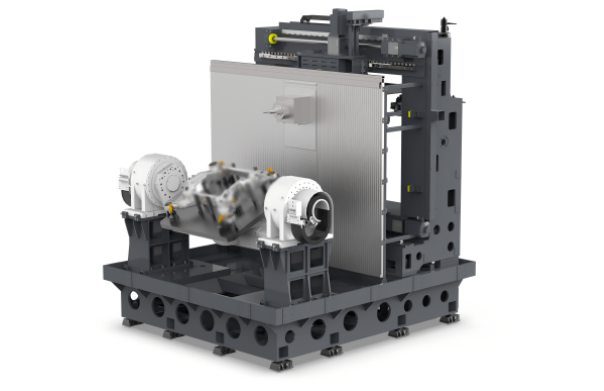

Five-axis profile machining center High-speed precision boring and milling compound

June 27, 2024

In modern manufacturing, five-axis profile machining centers have become key equipment for industrial processing with their excellent performance and precision. Especially in the field of high-speed precision boring and milling composite processing, the advantages of this equipment are particularly significant. This article will delve into the unique features of the five-axis profile machining center and its application in high-precision machining, and explain why it plays a vital role in high-speed precision boring and milling composite machining.

1. Introduction to five-axis machining center

The five-axis profile machining center is a highly automated processing equipment that achieves precision processing of complex parts through five different axes. This equipment can not only perform traditional cutting operations, but also process in multiple directions simultaneously, greatly improving processing efficiency and accuracy. Compared with traditional three-axis machining centers, five-axis machining centers can handle more complex geometries and are especially suitable for high-precision fields such as aerospace, automobile manufacturing, and mold manufacturing.

2. Advantages of high-speed precision boring and milling composite processing

High-speed precision boring and milling composite processing is a core technology of the five-axis profile machining center. This processing method combines the advantages of boring and milling and can complete high-precision processing tasks in a short time. Specifically, high-speed precision boring and milling composite processing has the following main advantages:

(1)Improve machining accuracy: Through the simultaneous movement of five axes, the profile five-axis machining center can complete the processing of complex shapes in a single fixture, reducing errors caused by repositioning, thereby significantly improving machining accuracy.

(2)Improve processing efficiency: Since the multi-axis operation of the five-axis machining center can be performed in multiple directions simultaneously, the overall processing time has been greatly shortened. This not only improves production efficiency, but also reduces production costs.

(3)Enhance flexibility: The five-axis machining center can process various materials, such as aluminum alloy, titanium alloy, etc., and is especially suitable for processing materials that require high strength and high hardness. Its flexible processing capabilities can cope with various complex-shaped parts requirements.

(4)Reduce the number of times the workpiece is clamped: In traditional processing, it may be necessary to clamp the workpiece multiple times to complete complex processing tasks. The five-axis machining center can complete all processing steps in one clamping, greatly reducing the number of clamping and processing errors.

3. Application examples

In the aerospace field, five-axis profile machining centers are particularly widely used. For example, aluminum alloy profiles and complex structural parts of aircraft fuselages usually require high-precision boring and milling to ensure their safety and reliability. By using five-axis machining centers, manufacturers can speed up production while ensuring machining accuracy.

In the automobile manufacturing industry, five-axis machining centers also play an important role. Modern automobile engine components, chassis parts, and various complex casings all require precision processing. High-speed precision boring and milling combined processing technology makes the production of these parts more efficient and precise, further improving the overall performance and reliability of the car.

4. Future Outlook

With the continuous advancement of technology, the functions and performance of five-axis profile machining centers are also constantly improving. Future five-axis machining centers may integrate more intelligent technologies, such as artificial intelligence and automated inspection systems, to further improve processing accuracy and production efficiency. Five-axis machining centers will also play an increasingly important role in green manufacturing and environmental protection.

in conclusion

The five-axis profile machining center has become an indispensable tool in modern manufacturing due to its technical advantages in high-speed and precision boring and milling compound processing. It not only improves processing accuracy and efficiency, but also enhances production flexibility. For industries that require high-precision processing, investing in a five-axis profile machining center is a key step to improve production capacity and competitiveness. If you are interested in the five-axis profile machining center or need to know more information, please feel free to consult us and we will wholeheartedly provide you with professional solutions.