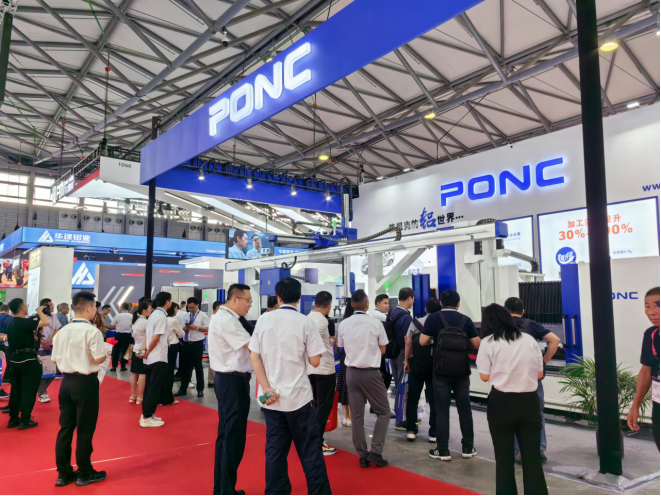

The first stop of the journey: PONC appeared at the Aluminum Industry Exhibition, leading the new direction of profile machine automation line

August 20, 2024

At grand opening of the Aluminum Industry Exhibition, a storm about intelligent manufacturing and efficiency revolution is sweeping across the entire Shanghai New International Expo Center. As one of the industry's focal points, PONC showcased its latest masterpiece - the automation production line of profile machines at booth 1C80 in Hall N1, bringing a smart feast about the future of aluminum profile processing to the audience.

Since its establishment, PONC has been committed to innovative research and development of profile processing equipment. This exhibition not only showcases Puenke's profound accumulation in the field of aluminum profile processing, but also interprets the research and development concept of "customer-centric" with practical actions, solving customer pain points.

At the core of Hall N1, PONC's automated profile machine production line became the focus of attention. This automation line is designed to solve the common problem of producing multiple types of parts in the current profile processing industry, with low product consistency? High labor costs? Does the automation line occupy a large area? Is it difficult to switch between manual and automated? Faced with these long-standing challenges that have plagued the industry, the machining center solution provided by Puenke, with its high cost-effectiveness, high efficiency, and high flexibility, brought a dual shock of visual and technological impact to the on-site audience.

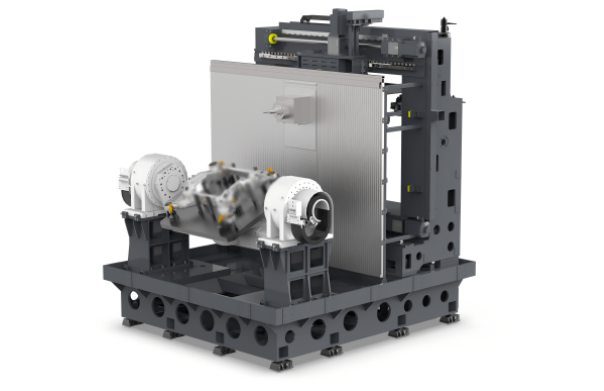

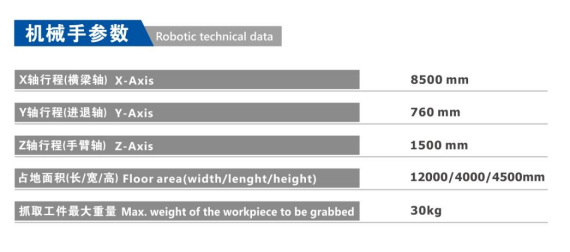

Firstly, the automated production line adopts a truss robotic arm design, which not only significantly reduces costs compared to traditional articulated robots, but also greatly saves valuable factory space. The robotic arm is installed above the equipment, which not only avoids the occupation of ground space, but also improves the overall planning and operation fluency of the workshop, providing strong support for the lean production of the enterprise.

Secondly, the intelligence level of this production line is impressive. From loading to clamping, and then to unloading, the entire process is precisely operated by robots, reducing manual intervention and significantly improving production efficiency and product quality consistency. This transformation is undoubtedly a shot in the arm for enterprises pursuing large-scale and high-precision production, which can help them gain an advantage in the fierce market competition.

It is particularly worth mentioning that PONC's automated production line for profile machines fully considers the user experience from the beginning of its design. The structure of its truss manipulator is not only easy to maintain, but also convenient for flexible switching between automated loading and unloading and manual loading and unloading, providing more choices for enterprises in different production stages. This humanized design concept undoubtedly won unanimous praise from the on-site audience.

On the stage of the aluminum industry exhibition, PONC showcased the power and charm of Chinese intelligent manufacturing to the world with its new automated profile machine production line, and also painted a hopeful blueprint for the future development of the industry.

As the exhibition deepens, we have reason to believe that PONC and its innovative products will shine on a broader stage, contributing to the transformation and upgrading of the profile processing industry.

Faced with many challenges in the aluminum processing industry, PONC has provided practical and feasible solutions for the industry with its new profile machine automation line as a breakthrough. In the future, PONC will continue to be market-oriented and contribute more wisdom and strength to the intelligent transformation of the profile processing industry.

More information can be clicked:PONC