What is a compound machining center

August 12, 2024

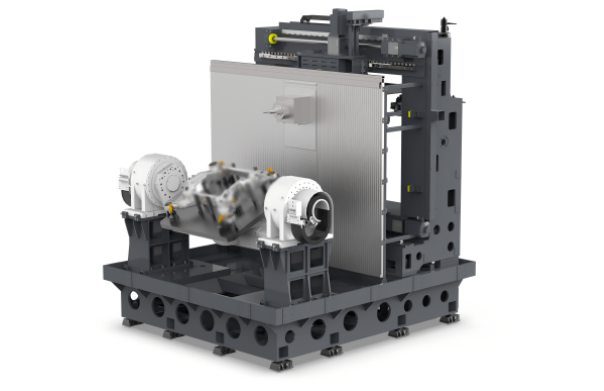

In modern manufacturing, composite machining centers have gradually become key equipment to improve production efficiency and processing accuracy. So what exactly is a composite machining center? Simply put, a composite machining center is a CNC machine tool that integrates multiple processing functions and can complete multiple processing steps on the same equipment. Its emergence has completely changed the traditional processing methods, improved production efficiency and processing accuracy, and brought significant changes to the manufacturing industry.

1. Basic definition of composite machining center

A compound machining center refers to a CNC machine tool that can complete multiple processing tasks on one workstation. Different from traditional processing methods, compound machining centers integrate multiple processing functions such as milling, drilling, and turning. This means that within one operation cycle, the composite machining center can complete complex workpiece manufacturing, greatly shortening the production cycle and improving production efficiency.

2. Main features

1. Multifunctional integration

The core advantage of the composite machining center lies in its multi-functional integration characteristics. Traditional processing methods often require the workpiece to be transferred from one machine tool to another for different processing steps, while the hybrid machining center can complete all processing steps on one device. For example, a composite machining center can perform turning, milling, drilling and tapping operations at the same time, which greatly reduces the number of workpiece handling and equipment footprint.

2. High precision and efficiency

Compound machining centers are usually equipped with high-precision CNC systems and high-rigidity machine tool structures, which effectively guarantees their processing accuracy and stability. Its efficient processing capabilities can significantly improve production efficiency, and by reducing the transfer and docking of workpieces, processing errors can be reduced, thereby improving the overall quality of the product.

3. Automation and intelligence

Modern composite machining centers also have the characteristics of automation and intelligence. Many high-end composite machining centers are equipped with automatic tool changing systems, automatic measurement systems and intelligent operating interfaces. These functions can achieve efficient automated processing, improve the intelligence level of the processing process, and reduce the technical requirements for operators.

3. Application fields

Composite machining centers are widely used in many fields. In industries such as aerospace, automobile manufacturing, medical equipment, and high-precision molds, the high efficiency and high-precision characteristics of composite machining centers make them indispensable equipment. For example, in aerospace manufacturing, composite machining centers can process complex aluminum alloy and titanium alloy parts; in automobile manufacturing, they can achieve high-precision machining of engine parts.

There are several key factors to consider when choosing a suitable composite machining center:

1. Processing requirements

It is necessary to select the appropriate composite machining center according to the actual processing needs. For example, whether turning functionality is required, the size of the machining range, and the required machining accuracy should all be considered during selection.

2. Stability and accuracy of machine tools

The stability and accuracy of machine tools directly affect the processing quality. When selecting, attention should be paid to the technical parameters of the machine tool to ensure that it can meet the production requirements.

3. After-sales service and technical support

Choosing a supplier with good after-sales service and technical support can help you get timely help when equipment problems arise and reduce downtime in production.

With the development of technology, composite machining centers are also making continuous progress. In the future, composite machining centers will be more intelligent and integrate more advanced functions, such as artificial intelligence-assisted processing, remote monitoring and automated production lines. These advances will further improve processing efficiency and precision, and promote the development of manufacturing industry in a more intelligent and automated direction.

Conclusion

As an advanced CNC machine tool, the compound machining center plays an important role in modern manufacturing due to its multi-functional integration, high precision and high efficiency. If you would like more details about composite machining centers or need help choosing the equipment that is right for you, please feel free to contact us. Our professional team will wholeheartedly provide you with the best service and advice.