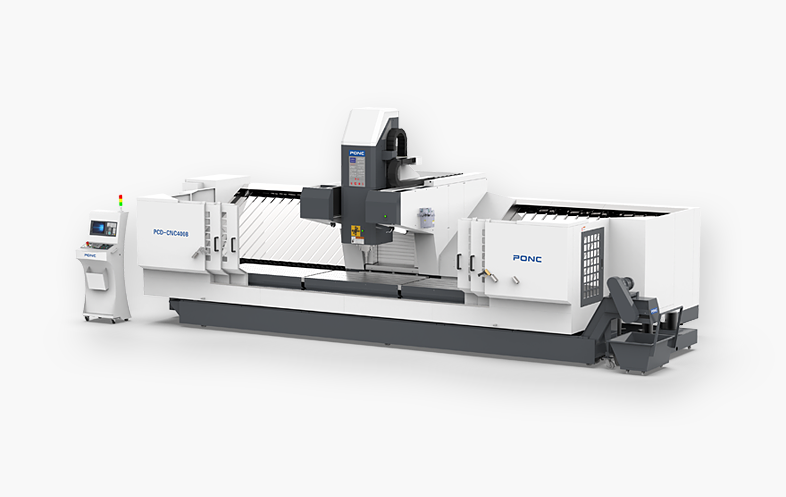

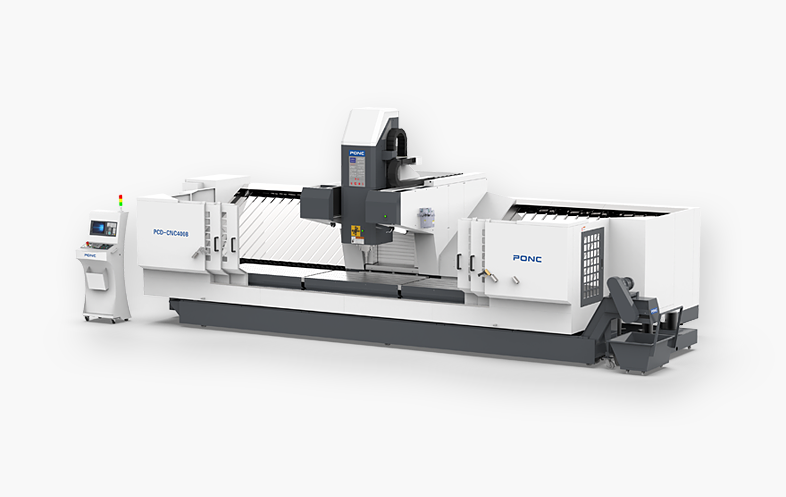

PCD Series Profile Machining Center

| Max. spindle speed | 12000 rpm |

| Max. spindle power | 42.4 kW |

| Max. rapid on X | 40 m/min |

| X-axis stroke | 4000/6000 mm |

| Y-axis stroke | 800/1200 mm |

| Z-axis stroke | 600 mm |

* Other lengths can be customized

| Max. spindle speed | 12000 rpm |

| Max. spindle power | 42.4 kW |

| Max. rapid on X | 40 m/min |

| X-axis stroke | 4000/6000 mm |

| Y-axis stroke | 800/1200 mm |

| Z-axis stroke | 600 mm |

* Other lengths can be customized

| Machine Parameter - PCD | ||

| TRAVELS | unit | Parameter |

|---|---|---|

| X-Axis | mm | 4000/6000 |

| Y-Axis | mm | 800/1200 |

| Z-Axis | mm | 600 |

| Spindle speed | rpm | 10000 |

| Spindle taper | / | BT40 |

| TOOL MAGAZINE | ||

| Type | / | Umbrella chain type |

| Max.pockets of tool magazine | pcs | 20 |

| Tool change time (tool to tool) | sec | 6 |

| AXIS FEED RATES | ||

| Rapid on X | m/min | 40 |

| Rapid on Y | m/min | 30 |

| Rapid on Z | m/min | 20 |

| X/Y/Z-Axis Cutting feed rate | mm/min | 15000 |

| LUBRICATION AND COOLING SYSTEM | ||

| Lubrication system | / | Automatic |

| Coolant system | / | Water cooling |

| ACCURACY | ||

| X-Axis Positioning accuracy | mm | 0.03 |

| Y/Z-Axis Positioning accuracy | mm | 0.015 |

| X/Y/Z-Axis Repeatability accuracy | mm | 0.015 |

| MECHANICAL SPECIFICATION | ||

| Required pneumatic pressure | kg/cm² | 6 |

| cnc system | / | SIEMENS/FANUC |

| Machine height | mm | 3700/3600/3500 |

| Floor area | mm | 9000/9300/11300/11400 x 3500 |

| Machine weight | T | 19/21/22/24 |

1. The PONC CNC machine PCD is a CNC composite profile machining center that integrates drilling, tapping, milling, and chamfering,

2. Use international specialized CNC numerical control system;

3. Suitable for processing steel, aluminum, copper metal and non-metal of various lengths;

4. Adopting a double cantilever design structure to increase equipment stability and rigidity, suitable for heavy-duty cutting, and improve machining accuracy;

5. Adopt a large inclined sheet metal organ cover for protection;

6. Adopting BT40/BT50 spindle taper holes increases machine rigidity, resulting in high processing efficiency, accuracy, and strength;

7. Different specifications of models can be customized according to customer requirements.