AUTOMOTIVE

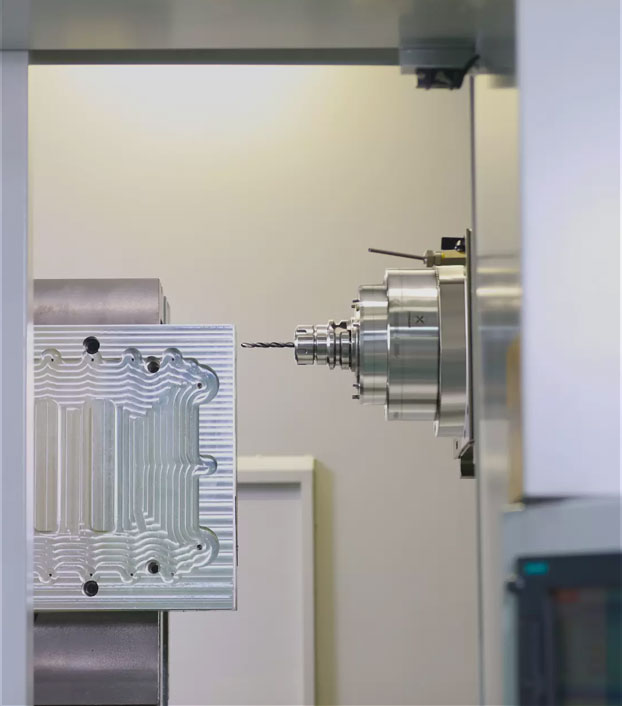

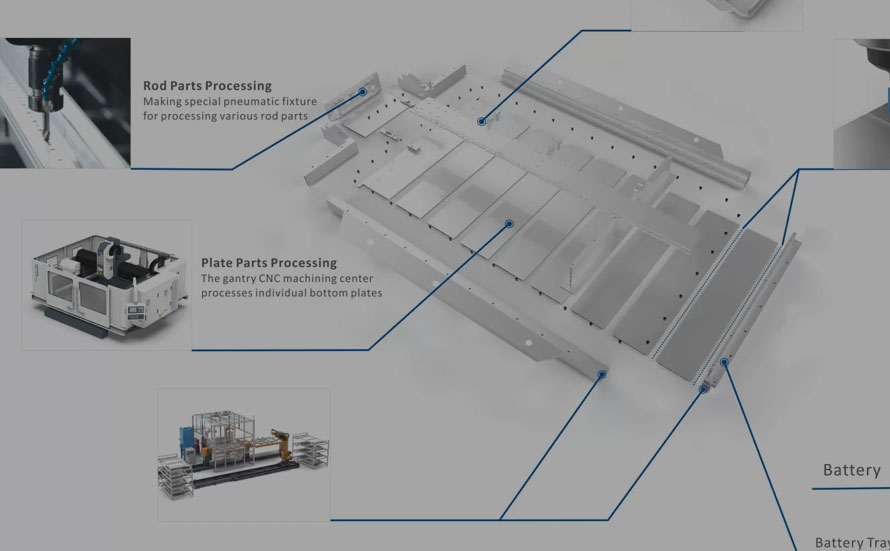

Automobile manufacturing – one of the key applications of Pratic machining centers.

The innovation rate and processing requirement in this field are often very high, also is a highly competitive industry, thus for the manufacturers and suppliers in this field, high efficiency and high return on investment is significantly important.